|

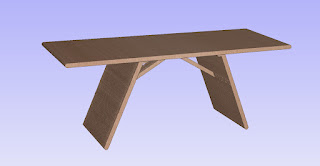

| Unfolded |

|

| Underside View |

For the folding action to work a precise connection point between leg panels and braces must be found. Through some iterative drafting steps I've been able to get within .001" of where it is. To fold flat both the leg panels and the braces have an offset end. The leg panels are one inch narrower than the table top. The flip panels and braces are tucked under the top to minimize their visual impact on the stance of the table.

|

| Leg Panels |

|

| Flip Panels and Braces |

When folding up the flip panels flip over and out of the way so the braces can lay down flat against the top.

Folded flat.

The pivoting connections are the only challenge left to resolve. The flip panels connect/pivot from the top underside and have to flip 180 degrees over where they connect. The braces connect to both the underside of the top and near the center of the leg panels. Some clearance between pivoting parts and where they pivot from is needed to prevent wood from rubbing against wood as they pivot. 1/8" (3mm) Baltic birch plywood could be used as the pivot brackets extending from the bottom face of the table top. Glued into a slot they would be a challenge to remove/replace if they ever fail though. Plate brass or aluminum could be used but would need a mechanical connection into the table top. This connection deserves an original design solution.

The leg panels have openings for the flip panel and the braces. Making each leg from three sections assembled to capture the other parts would be the obvious strategy. I need a way to mechanically do this so they can be taken apart should any piece fail. My intersecting binding bolt trick I used on the last two TV tray tables might work. I'd like to figure out a way to have the action of bolting them in also snug the joint tight. Some sort of cam or lever action. There is a double end cam solution already out there used for knock-down furniture that might work.

It wouldn't take much to modify the geometry to side table dimensions. Longer legs and a shorter top might require one leg to fold over the other to keep the folded length within the length of the top.

My house is overrun with coffee tables so I doubt I'll ever build this design. It is parked here for future reference so I can clear the idea from my mind and let it fill up with newer ideas.