|

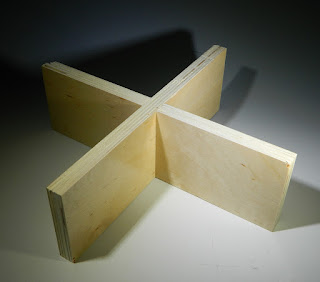

| Halving Joint |

The disadvantage of the joint is when you want it snug you have to take care when cutting each side. Yet when it is a very good fit the simple act of sliding the joint together can scrap off finish or mar the surface.

I came up with a CNC cut version that is easy to slide together yet is very snug when assembled. Both sides of the joint can be cut from the top side of the boards laying flat on the bed of the CNC. I've used this joint several times between Baltic Birch plywood parts, and between two different thicknesses of hard maple for a student's project.

|

| Render from Aspire Software |

|

| Each Side Identical |

When the thickness of the material is carefully measured, and the CNC toolpaths are done right this joint slides easily down until about 1/16" from closed. A tap with a wood mallet drives it the last 1/16" for a joint so tight it'll take the mallet to open it up again.

The ramped side helps the plywood stay perfectly aligned as it slides together.

|

| Almost Together |

A CNC file made for Vectric's Aspire or VCarve Pro/Desktop can be found HERE. The slope made on the face of the boards was done with the fluting toolpath and a few parallel vectors. I used a 3/16"d downcut spiral router bit for all the cuts. If done with material thicker than 3/4" a larger diameter bit may be needed.

Questions and Comments are welcomed and encouraged.

4D