I spent the last 10 years using CNCs without a tool changer. Whenever the job required a bit change normally I thought about how I might be able to do the job using just one bit and some creative use of the CNC software I was using. This is one example.

Projects that needed perimeter or internal chamfers were done most efficiently with a bit change to a V bit. I have a project that is put together with flat head bolts. The need to chamfer the bolt holes could have been done using a drill press after the CNC was done. Figuring out how to chamfer a hole with the same end mill I used for all the other cuts turned a 2 process job into one CNC job with no bit changes.

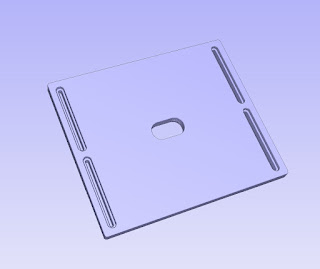

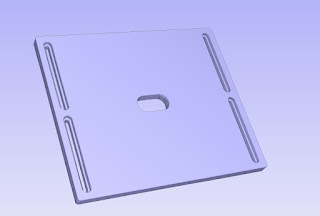

Vectric.com's Aspire and VCarve programs have a fluting toolpath. Fluting takes a vector and ramps the bit down or down then up with the bit being centered on the vector. A circular array of 9 (or more) short vectors centered over the bolt hole, using a bit no larger than the diameter of the hole, can effectively chamfer the perimeter of the hole from the bolt head diameter down to the hole edge. Using a small bit (1/8" or 1/16") may require a greater number of vectors to result in a relatively smooth chamfered edge. The chamfers in this image were made with a 1/4" diameter end mill.

|

| 2 x 2 Hole Array |

|

| Vectors Used |

Questions or comments are encouraged!

4D